-

Fuel cell

Product introduction (1) 280 wheelbase, the boom adopts 3.0mm thick carbon fiber board, and the fuselage thickness is 1.5mm carbon fiber board, which ensures the strength of the aircraft in flight and effectively reduces vibration; (2) The whole unmanned frame is made of pure carbon fiber board, which is light in weight, and the whole empty machine weighs 135g (including the spare parts of UAV such as bolt aluminum column), which is small in volume and long in service life (3) The fuselage is... -

Hydrogen cylinder

Product introduction (1) 280 wheelbase, the boom adopts 3.0mm thick carbon fiber board, and the fuselage thickness is 1.5mm carbon fiber board, which ensures the strength of the aircraft in flight and effectively reduces vibration; (2) The whole unmanned frame is made of pure carbon fiber board, which is light in weight, and the whole empty machine weighs 135g (including the spare parts of UAV such as bolt aluminum column), which is small in volume and long in service life (3) The fuselage is... -

Hydrogen energy bicycle

Product introduction (1) 280 wheelbase, the boom adopts 3.0mm thick carbon fiber board, and the fuselage thickness is 1.5mm carbon fiber board, which ensures the strength of the aircraft in flight and effectively reduces vibration; (2) The whole unmanned frame is made of pure carbon fiber board, which is light in weight, and the whole empty machine weighs 135g (including the spare parts of UAV such as bolt aluminum column), which is small in volume and long in service life (3) The fuselage is... -

Portable fuel cell power generation products

Product introduction (1) 280 wheelbase, the boom adopts 3.0mm thick carbon fiber board, and the fuselage thickness is 1.5mm carbon fiber board, which ensures the strength of the aircraft in flight and effectively reduces vibration; (2) The whole unmanned frame is made of pure carbon fiber board, which is light in weight, and the whole empty machine weighs 135g (including the spare parts of UAV such as bolt aluminum column), which is small in volume and long in service life (3) The fuselage is... -

Carbon fiber UAV Rack-Hydrogen Energy

Product introduction (1) 280 wheelbase, the boom adopts 3.0mm thick carbon fiber board, and the fuselage thickness is 1.5mm carbon fiber board, which ensures the strength of the aircraft in flight and effectively reduces vibration; (2) The whole unmanned frame is made of pure carbon fiber board, which is light in weight, and the whole empty machine weighs 135g (including the spare parts of UAV such as bolt aluminum column), which is small in volume and long in service life (3) The fusela... -

Decompression valve

Product introduction (1) 280 wheelbase, the boom adopts 3.0mm thick carbon fiber board, and the fuselage thickness is 1.5mm carbon fiber board, which ensures the strength of the aircraft in flight and effectively reduces vibration; (2) The whole unmanned frame is made of pure carbon fiber board, which is light in weight, and the whole empty machine weighs 135g (including the spare parts of UAV such as bolt aluminum column), which is small in volume and long in service life (3) The fuselage is... -

Plastic reinforcement chopped carbon fiber

The carbon fiber chopped strand are based on the polyacrylonitrile fiber as the raw material. Via carbonization, special surface treatment, mechanical grinding, sieving and drying.

-

Fuel Tank Strap-Thermoplastic

A fuel tank strap is a support of the oil or gas tank on your vehicle. It is often a C type or U type belt strapped around the tank. The material is now often metal but can be also non-metal. For fuel tanks of cars, 2 straps are usually enough, but for large tanks for special use (e.g. underground storage tanks), more quantities are needed.

-

Sandwich Panels Series

This Sandwich Panel product uses outer skin as the core, which made by continuous glass fiber (high strength, high rigidity and high toughness) mixed with thermoplastic resin. then composite with polypropylene (PP) honeycomb core through Continuous thermal lamination process.

-

High temperature resistant carbon fiber board

We use the battery box made of fiber composite materials to help you improve your travel efficiency tomorrow. Compared with traditional materials, their weight is greatly reduced, longer range can be achieved, and other important requirements in safety, economy and thermal management can be met. We also support the new modern electric vehicle platform

-

Fabrication of prepreg- Carbon fiber raw material

Fabrication of prepreg Carbon fiber prepreg is composed of continuous long fiber and uncured resin. It is the most commonly used raw material form for making high-performance composites. Prepreg cloth is composed of a series of fiber bundles containing impregnated resin. The fiber bundle is first assembled into the required content and width, and then the fibers are evenly separated through the fiber frame. At the same time, the resin is heated and coated on the upper and lower release p... -

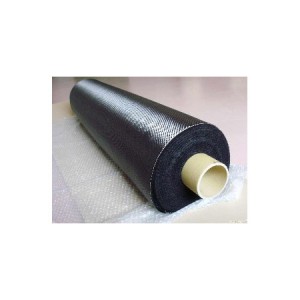

Carbon fiber Fabric-Carbon fiber fabric composites

Carbon fiber Fabric Carbon Fiber Fabric is made of carbon fiber by woven unidirectional, plain weaving or twill weaving style. The carbon fibers we use contain high strength-to-weight and stiffness-to-weight ratios, carbon fabrics are thermally and electrically conductive and exhibit excellent fatigue resistance. When properly engineered, carbon fabric composites can achieve the strength and stiffness of metals at significant weight savings. Carbon fabrics are compatible with various res...

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu