Plastic reinforcement chopped carbon fiber

Chopped carbon fiber

Short-cut carbon fibers have good fluidity, and the shorter the length, the better the fluidity. By mixing short-cut carbon fibers with resin and granulating, then using injection molding to make various products, large-scale production can be achieved.

In the composite material industry, according to the range of matrix resin usage, it is required that the sizing agent must be compatible with the final matrix during the manufacturing process. In recent years, the progress in slurry chemical properties has led the industry to shift from solvent-based slurries to water-based slurries, making the sizing process cleaner and more environmentally friendly.

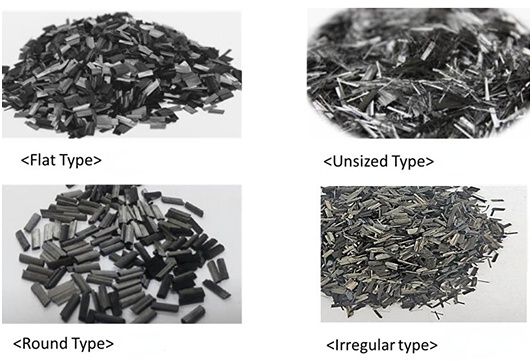

There are four common types of short-cut carbon fibers: sheet-shaped, cylindrical, irregular, and unsized. The feeding capacity of twin-screw equipment is: cylindrical > sheet-shaped > irregular > unsized (unsized short-cut fibers are not recommended for twin-screw equipment use).

Thermoplastic carbon fiber particles with PI/ PEEK

Among them, cylindrical short-cut carbon fibers have higher requirements for raw materials and processing equipment, but their performance is also better.

Below is some technical parameter of our chopped carbon fiber for your reference.

|

Raw material |

Sizing content |

Sizing type |

Other information |

|

50K or 25K*2 |

6 |

polyamide |

Sizing can be customized |

|

Item |

Standard value |

Average value |

Test standard |

|

Tensile Strength (Mpa) |

≥4300 |

4350 |

GB/T3362-2017 |

|

Tensile Modulus (Gpa) |

235~260 |

241 |

GB/T3362-2017 |

|

Elongation at break |

≥1.5 |

1.89 |

GB/T3362-2017 |

|

Sizing |

5~7 |

6 |

GB/T26752-2020 |

We can not only produce thermosetting carbon fiber short fibers, but also produce thermoplastic short-cut carbon fibers. It all depends on your requirements

Thermoplastic carbon fiber particles with PI/ PEEK

Advantage:High strength, high modulus, electrical conductivity

Usage: EMI shielding, Antistatic, reinforcement the engineering plastic

| Material | Carbon fiber & PI/PEEK |

| Carbon fiber Content (%) | 97% |

| PI/PEEK content(%) | 2.5-3 |

| Water Content(%) | <0.3 |

| Length | 6mm |

| Thermal stability of surface treatment | 350℃ - 450 ℃ |

| Recommended use | Nylon6/66, PPO, PPS, PEI, PES, PPA, PEEK, PA10T, PEKK, PPS,PC, PI, PEEK |