OEM/ODM Factory Thin Carbon Fiber Sheets - Fabrication of prepreg- Carbon fiber raw material – WANHOO

OEM/ODM Factory Thin Carbon Fiber Sheets - Fabrication of prepreg- Carbon fiber raw material – WANHOO Detail:

Fabrication of prepreg

Carbon fiber prepreg is composed of continuous long fiber and uncured resin. It is the most commonly used raw material form for making high-performance composites. Prepreg cloth is composed of a series of fiber bundles containing impregnated resin. The fiber bundle is first assembled into the required content and width, and then the fibers are evenly separated through the fiber frame. At the same time, the resin is heated and coated on the upper and lower release paper. The fiber and the upper and lower release paper coated with resin are introduced into the roller at the same time. The fiber is located between the upper and lower release paper, and the resin is evenly distributed between the fibers by the pressure of the roller. After the resin impregnated fiber is cooled or dried, it is rolled into a reel shape by a coiler. The resin impregnated fiber surrounded by upper and lower release paper is called carbon fiber prepreg. The rolled prepreg needs to be gelatinized to the stage of partial reaction under the controlled temperature and humidity environment. At this time, the resin is solid, which is called B-stage.

Generally, when making carbon fiber prepreg cloth, the resin adopts two types. One is to directly heat the resin to reduce its viscosity and facilitate uniform distribution among the fibers, which is called hot melt adhesive method. The other is to melt the resin into the flux to reduce the viscosity, and then heat it after the resin is impregnated with fiber to volatilize the flux, which is called flux method. In the process of hot melt adhesive method, the resin content is easy to control, the drying step can be omitted, and there is no residual flux, but the resin viscosity is high, which is easy to cause fiber deformation when impregnating fiber braids. Solvent method has low investment cost and simple process, but the use of flux is easy to remain in the prepreg, which affects the strength of the final composite and causes environmental pollution.

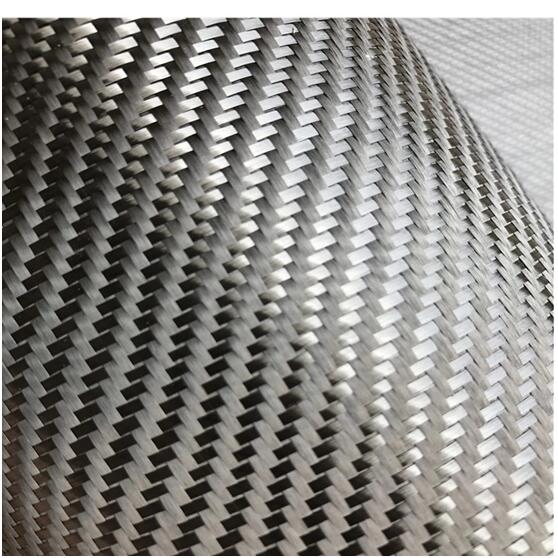

The types of carbon fiber prepreg cloth include unidirectional carbon fiber prepreg cloth and woven carbon fiber prepreg cloth. Unidirectional carbon fiber prepreg cloth has the greatest strength in the fiber direction and is usually used for laminated plates combined in different directions, while woven carbon fiber prepreg cloth has different weaving methods, and its strength is about the same in both directions, so it can be applied to different structures.

we can provide with carbon fiber prepreg according to your requirements

Storage of prepreg

The resin of carbon fiber prepreg is in the stage of partial reaction, and will continue to react and cure at room temperature. It usually needs to be stored in a low temperature environment. The time that carbon fiber prepreg can be stored at room temperature is called storage cycle. Generally, if there is no low-temperature storage equipment, the production amount of prepreg must be controlled within the storage cycle and can be used up.

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for OEM/ODM Factory Thin Carbon Fiber Sheets - Fabrication of prepreg- Carbon fiber raw material – WANHOO , The product will supply to all over the world, such as: Belize, Philadelphia, Gambia, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.