OEM China Low Temp Prepreg Carbon Fiber - Plastic reinforcement chopped carbon fiber – WANHOO

OEM China Low Temp Prepreg Carbon Fiber - Plastic reinforcement chopped carbon fiber – WANHOO Detail:

Chopped carbon fiber

The carbon fiber chopped strand are based on the polyacrylonitrile fiber as the raw material. Via carbonization, special surface treatment, mechanical grinding, sieving and drying.

It is stable, electrical conductive, self-lubricating and reinforcing. Because of that It can composite with resin ,plastic, metal, rubber and so on. So It can reinforce the strength and wear resistance of the materials.

It can also be commonly compounded with general engineering thermoplastics (e.g., PC, Nylon, etc.) and high-temperature thermoplastic resins (e.g, PEEK, PEI, etc.), the resulting composite offers industry-leading high strength-to-weight and stiffness-to-weight ratios.

Now It is used in many fields. For examples: Electronic chips, conducting plate, conducting floor, Electronic machinery, anti-static industries, anti-static filter, defense industry, building insulation, chemical.

CFRP are composite materials. In this case the composite consists of two parts: a matrix and a reinforcement. In CFRP the reinforcement is carbon fiber, which provides its strength. The matrix is usually a polymer resin, such as epoxy, to bind the reinforcements together. Because CFRP consists of two distinct elements, the material properties depend on these two elements.

Reinforcement gives CFRP its strength and rigidity, measured by stress and elastic modulus respectively. Unlike isotropic materials like steel and aluminum, CFRP has directional strength properties. The properties of CFRP depend on the layouts of the carbon fiber and the proportion of the carbon fibers relative to the polymer. The two different equations governing the net elastic modulus of composite materials using the properties of the carbon fibers and the polymer matrix can also be applied to carbon fiber reinforced plastics

below is the our products in the application of carbon fiber reinforced plastics

Thermoplastic carbon fiber particles with PI/ PEEK

Advantage:High strength, high modulus, electrical conductivity

Usage: EMI shielding, Antistatic, reinforcement the engineering plastic

| Material | Carbon fiber & PI/PEEK |

| Carbon fiber Content (%) | 97% |

| PI/PEEK content(%) | 2.5-3 |

| Water Content(%) | <0.3 |

| Length | 6mm |

| Thermal stability of surface treatment | 350℃ - 450 ℃ |

| Recommended use | Nylon6/66, PPO, PPS, PEI, PES, PPA, PEEK, PA10T, PEKK, PPS,PC, PI, PEEK |

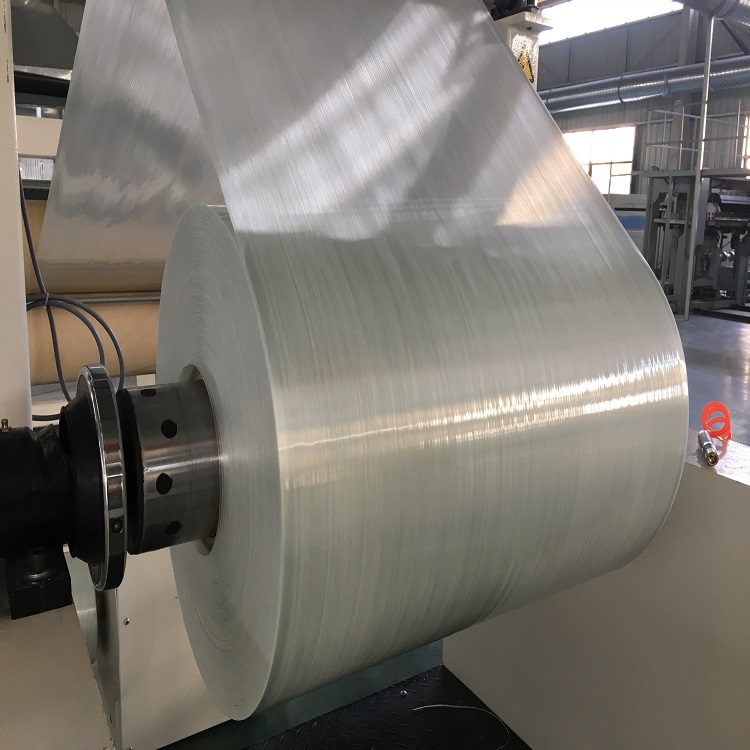

Product detail pictures:

Related Product Guide:

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for OEM China Low Temp Prepreg Carbon Fiber - Plastic reinforcement chopped carbon fiber – WANHOO , The product will supply to all over the world, such as: azerbaijan, Bogota, Guatemala, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.