With the continuous expansion of the application market, thermosetting resin based carbon fiber composites gradually show their own limitations, which can not fully meet the high-end application needs in the aspects of wear resistance and high temperature resistance. In this case, the status of thermoplastic resin based carbon fiber composites is gradually rising, becoming a new force of advanced composites. In recent years, the Chinese carbon fiber technology has made rapid development, and the application technology of thermoplastic carbon fiber composites has also been further promoted.

In the exploration of continuous carbon fiber reinforced thermoplastic pre preg, three trends of application of thermoplastic carbon fiber are vividly demonstrated

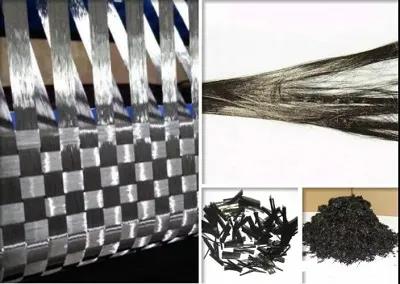

1. From powder carbon fiber reinforced to continuous carbon fiber reinforced

Carbon fiber thermoplastic composites can be divided into powder carbon fiber, chopped carbon fiber, unidirectional continuous carbon fiber and fabric carbon fiber reinforcement. The longer the reinforced fiber is, the more energy is provided by the applied load, and the higher the overall strength of the composite. Therefore, compared with powder or chopped carbon fiber reinforced thermoplastic composites, continuous carbon fiber reinforced thermoplastic composites have better performance advantages. The most widely used injection molding process in China is powder or chopped carbon fiber reinforced. The performance of products has certain limitations. When continuous carbon fiber reinforced is used, thermoplastic carbon fiber composites will usher in a wider application space.

2. The development from low end thermoplastic resin to medium and high end thermoplastic resin matrix

Thermoplastic resin matrix shows high viscosity during melting process, which is difficult to fully infiltrate carbon fiber materials, and the degree of infiltration is closely related to the performance of prepreg. In order to further improve the wettability, the composite modification technology was adopted, and the original fiber spreading device and resin extrusion equipment were improved. While extending the width of carbon fiber strand, the continuous extrusion amount of resin was increased. The wettability of thermoplastic resin on carbon fiber dimension was obviously improved, and the performance of continuous carbon fiber reinforced thermoplastic prepreg was effectively guaranteed. The resin matrix of continuous carbon fiber thermoplastic composites was successfully extended from PPS and PA to PI and peek.

3. From laboratory handmade to stable mass production

From the success of small-scale experiments in the laboratory to the stable mass production in the workshop, the key is the design and adjustment of production equipment. Whether the continuous carbon fiber reinforced thermoplastic prepreg can achieve stable mass production depends not only on the average daily output, but also on the quality of the prepreg, that is, whether the resin content in the prepreg is controllable and the proportion is appropriate, whether the carbon fiber in the prepreg is evenly distributed and thoroughly infiltrated, and whether the surface of the prepreg is smooth and the size is accurate.

Post time: Jul-15-2021