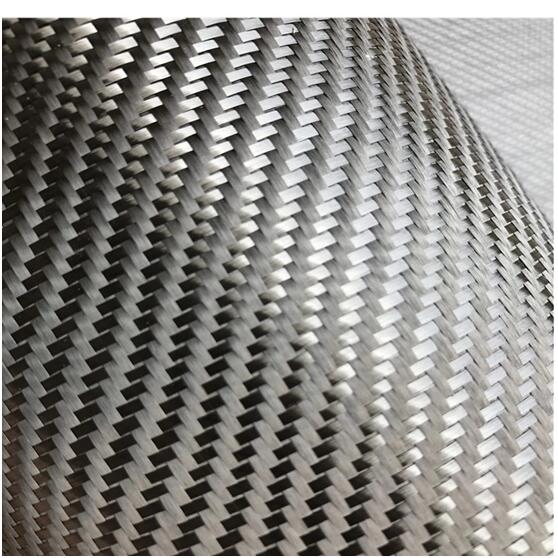

High Quality Twill Weave Carbon - Plastic reinforcement chopped carbon fiber – WANHOO

High Quality Twill Weave Carbon - Plastic reinforcement chopped carbon fiber – WANHOO Detail:

Chopped carbon fiber

The carbon fiber chopped strand are based on the polyacrylonitrile fiber as the raw material. Via carbonization, special surface treatment, mechanical grinding, sieving and drying.

It is stable, electrical conductive, self-lubricating and reinforcing. Because of that It can composite with resin ,plastic, metal, rubber and so on. So It can reinforce the strength and wear resistance of the materials.

It can also be commonly compounded with general engineering thermoplastics (e.g., PC, Nylon, etc.) and high-temperature thermoplastic resins (e.g, PEEK, PEI, etc.), the resulting composite offers industry-leading high strength-to-weight and stiffness-to-weight ratios.

Now It is used in many fields. For examples: Electronic chips, conducting plate, conducting floor, Electronic machinery, anti-static industries, anti-static filter, defense industry, building insulation, chemical.

CFRP are composite materials. In this case the composite consists of two parts: a matrix and a reinforcement. In CFRP the reinforcement is carbon fiber, which provides its strength. The matrix is usually a polymer resin, such as epoxy, to bind the reinforcements together. Because CFRP consists of two distinct elements, the material properties depend on these two elements.

Reinforcement gives CFRP its strength and rigidity, measured by stress and elastic modulus respectively. Unlike isotropic materials like steel and aluminum, CFRP has directional strength properties. The properties of CFRP depend on the layouts of the carbon fiber and the proportion of the carbon fibers relative to the polymer. The two different equations governing the net elastic modulus of composite materials using the properties of the carbon fibers and the polymer matrix can also be applied to carbon fiber reinforced plastics

below is the our products in the application of carbon fiber reinforced plastics

Thermoplastic carbon fiber particles with PI/ PEEK

Advantage:High strength, high modulus, electrical conductivity

Usage: EMI shielding, Antistatic, reinforcement the engineering plastic

| Material | Carbon fiber & PI/PEEK |

| Carbon fiber Content (%) | 97% |

| PI/PEEK content(%) | 2.5-3 |

| Water Content(%) | <0.3 |

| Length | 6mm |

| Thermal stability of surface treatment | 350℃ - 450 ℃ |

| Recommended use | Nylon6/66, PPO, PPS, PEI, PES, PPA, PEEK, PA10T, PEKK, PPS,PC, PI, PEEK |

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for High Quality Twill Weave Carbon - Plastic reinforcement chopped carbon fiber – WANHOO , The product will supply to all over the world, such as: Hungary, Jamaica, British, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!