High definition Cfrp Panels - Dry Cargo Box panel-Thermoplastic – WANHOO

High definition Cfrp Panels - Dry Cargo Box panel-Thermoplastic – WANHOO Detail:

The Introduction of Dry Cargo Box

Dry cargo box, sometimes also called dry freight container, has become a vital part of the supply-chain infrastructure. After intermodal container transportation, cargo boxes take the tasks of last-mile delivery. Traditional cargos are usually in metal materials, however recently, a new material–composite panel–is making a figure in the production of dry cargo boxes.

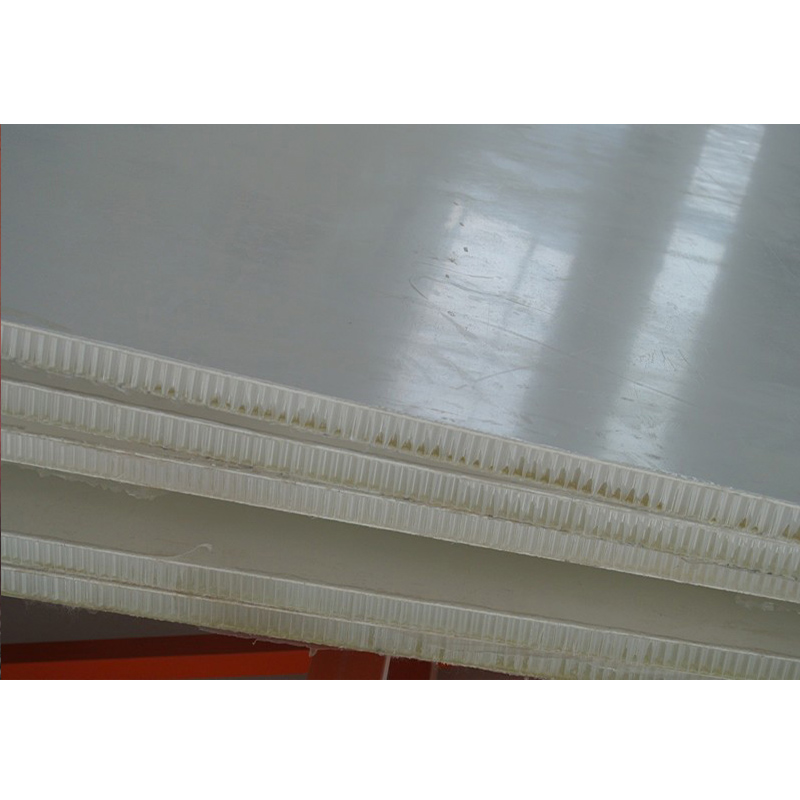

composite sandwich panel is an ideal choice for dry cargo boxes.

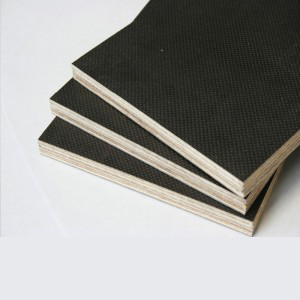

Why choose CFRT skin for PP honeycomb panels

Continuous glass fibers provide better strength. Flexible lay-up design can provide force in any direction. CFRT contain PP resin, it can be heated and laminated on PP honeycomb panel directly, so it can save the cost of film or glue. The surface can be designed to be anti slip. Lighter and recyclable. Waterproof and moisture proof

The major advantages are as follow

Lightweight

Continuous fiber-reinforced thermoplastic panels are much lighter than metal ones. In making cargo containers, this is the biggest advantage for freight loading.

Recyclable

Thermoplastic materials are 100% recyclable. They contribute more to the environment than metal materials.

High strength

Being lightweight, the composite cargo box panels are no less strong in impact resistance, even stronger than metal containers. This is because the continuous fiber in the material significantly reinforces the strength of cargo panels.

In addition to last-mile delivery, dry cargo box panels are also customizable for various applications, such as:

Small package containers (using 8mm to 10mm honeycomb panels or 3mm composite sheets)

Fragile product containers (for antiques and luxury car storage)

Reefer trailers and cold vans (The special thermo-property can help to keep the temperature in the containers.)

General-purpose containers

Shells of electric appliance

Our products are developed specifically for truck and trailer manufacturers and refrigeration units dealers. The innovative building and assembly method will cut down on your manufacturing costs and will give you the cutting edge over your competition. All parts are flat packed, cut to exact size and include the most advanced food safe adhesive.

Product detail pictures:

Related Product Guide:

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for High definition Cfrp Panels - Dry Cargo Box panel-Thermoplastic – WANHOO , The product will supply to all over the world, such as: Lithuania, South Korea, Kenya, Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!